Rethinking Quality Control: Automated Data Entry Validation with LLMs or CNNs

Automated quality control in incoming data – whether documents, image data, CAD files, or other formats – is the key to greater efficiency, reliability, and GDPR compliance. Incorrect or incomplete data leads to unnecessary costs, delays in production and processing, and customer satisfaction issues.

Our state-of-the-art technologies, including Large Language Models (LLMs), Convolutional Neural Networks (CNNs), and specialized validation tools, set new standards for you. Automate inspection processes with Chimaera, improve data quality, and ensure your processes run smoothly – from capture to further processing.

Applications

- Medical diagnostics and treatment planning

- Patient safety and medical documentation

- Research and studies

- Financial auditing

- Supply chain optimization

- Compliance

Solutions

- Document review

- Data extraction and validation

- 3D data analysis

- Image and video data processing

- Automated communication

Benefits

- Increased efficiency: Automation reduces processing time.

- Minimize errors: AI-based inspection processes eliminate human error.

- Flexibility: Adapt to different data formats and specific requirements.

- Scalability: Easily adapt to growing data volumes.

With Chimaera, you can revolutionize your data input processes – for more quality, reliability and cost efficiency.

Together, we will develop a solution that perfectly adapts to your requirements.

The Challenges of Incoming Data

In today's business environment, companies are faced with the task of checking ever larger and more complex volumes of data. The spectrum of data ranges from invoices and delivery bills to CAD data and medical images. Manual checking processes are time-consuming, error-prone, and inefficient. To address these challenges, companies are turning to automation through the targeted use of state-of-the-art AI technologies.

How can LLMs and CNNS assist in the analysis and structuring of large data sets in a short time frame, while identifying potential errors?

The use of LLMs and CNNs enables the handling of a wide variety of data formats. For instance, they can analyze documents such as PDF files, Excel spreadsheets, or Word documents to ensure the inclusion of all relevant information. In conjunction with specialized tools, AI can also evaluate and compare other types of data, including 3D data, image data, and video data.

Innovative Solutions with LLMs and CNNs

Our technologies help you to efficiently analyze data in a wide variety of formats, detect errors and optimize processes:

- Document Verification:

LLMs review documents such as invoices, customs documents, and bills of lading for completeness, inconsistencies, and discrepancies.

- Data Extraction and Validation:

Using natural language processing (NLP) technologies, we extract relevant information from unstructured or semi-structured text and compare it to target data, such as ERP systems.

- 3D Data Analysis:

CAD files in formats such as STL or DWG are analyzed to ensure that they meet the manufacturing requirements.

- Image and Video Processing:

We use advanced computer vision algorithms to detect defects in products or packaging.

In medicine in particular, we support the analysis of imaging data such as X-rays or MRIs.

- Automated Communication:

LLMs generate reports, highlight variances and suggest actions.

They act as an interface between systems and people to enable seamless integration.

Web App for Automated Data Input Checks

Another important aspect of our solutions is the ability to develop a web application or web interface for you. This tool allows your customers or users to upload data directly, making the inspection process even more user-friendly and efficient.

The web application provides the following features and benefits:

- Direct data verification: The uploaded data (e.g. images, CAD models or documents) can be displayed directly in the interface. Users can perform a visual review that highlights potential errors or inconsistencies directly on the data object.

- Automatic feedback: If there are problems with the data, the client is notified via the web application. Alternatively, we can integrate automatic email feedback that provides details of the errors found.

- Seamless integration: The web application can be adapted to existing systems so that the results flow directly into your workflows.

With this user-friendly platform, we not only make it easy to meet your needs, but also bring transparency and efficiency to the inspection process.

Data Quality Management and Automated Processing of CBCT Data in Arthroplasty

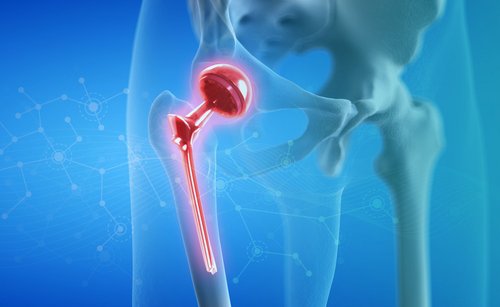

The processing and use of Cone Beam Computed Tomography (CBCT) data opens up a wide range of possibilities for the automation and optimization of processes in medicine. Particularly in the fields of arthroplasty, dental implantology and surgical planning, this technology enables personalized and precise solutions for automated data input.

CBCT Data Input Verification

Accurate data input verification is the first step in efficient CBCT data processing:

- Verify DICOM data: ensure completeness and compatibility.

- Image quality analysis: check for technical artifacts, insufficient resolution or contrast.

Production of Customized Implants

CBCT data provides the basis for the manufacture of customized medical solutions:

- Orthopedic implants: Producing hip, knee and shoulder replacements that fit the individual's anatomy.

- Maxillofacial surgery: Development of patient-specific plates and implants for reconstruction after accidents or tumor surgery.

- Automated segmentation: Using AI to extract relevant structures from CBCT data.

- 3D modeling: Design and manufacture implants using 3D printing or CNC milling from digitized models.

Benefits of Uploading CBCT Data to the Manufacturer

- High-resolution 3D visualization: Accurate analysis and planning through detailed visualization.

- Customization: Customized solutions for implants and surgical tools.

- Time savings: Automated processes accelerate planning and production.

- Seamless integration: Use with digital planning and CAD/CAM systems for efficient workflow.

Production of Customized Implants

CBCT data provides the basis for the manufacture of customized medical solutions:

- Orthopedic implants: Producing hip, knee and shoulder replacements that fit the individual's anatomy.

- Maxillofacial surgery: Development of patient-specific plates and implants for reconstruction after accidents or tumor surgery.

- Automated segmentation: Using AI to extract relevant structures from CBCT data.

- 3D modeling: Design and manufacture implants using 3D printing or CNC milling from digitized models.

Simulation and Surgical Planning

CBCT data is essential for preoperative simulation and optimized interventions:

- Virtual 3D models: Create realistic models of the skeletal system and adjacent structures.

- Implant positioning: Simulation and validation of optimal prosthesis or screw placement.

- Examples include: Planning knee replacements with individual biomechanics in mind, or simulating dental implants for optimal integration.

Navigation and Intraoperative Support

CBCT data is used to increase precision during surgery:

- Navigation systems: Development of 3D models that serve as the basis for surgical navigation aids.

- Intraoperative integration: Real-time integration of CBCT data with imaging modalities for precise implant placement.

Post-operative analysis and follow-up

CBCT data is also a valuable tool after surgery:

- Implant control: Comparison of preoperative planning with surgical results.

- Bone growth analysis: Monitoring of implant integration and detection of potential complications such as loosening or malpositioning.

Dental Implantology: Planning and Realization

Precise planning of dental implants benefits greatly from CBCT data:

- Analysis of the jaw structure: Identification of relevant anatomical features such as nerves or blood vessels.

- Creation of surgical guides: Automated planning and fabrication of customized guides for implant placement.

- Virtual implant positioning: Optimize placement based on bone quality and density.

Chimaera: Your Experts for AI-supported Quality Control

We offer customized solutions for incoming data inspection, adapted to your specific requirements:

- Checking and analyzing document content (PDF, Excel, Word, text).

- Quality checks for CAD data: STL, PLY, DWG, DWF, DWFX, DWT, DGN, DXB, OBJ, STL, CF2, IGES, IFC, PLT, and DXF.

- Processing of image and video data.

- Analysis of medical image data such as X-ray, CBCT, DVT, MR, US.

- Verification of DICOM data.

By integrating LLMs and CNNs into your data validation processes, you will benefit from

- Increased efficiency: Automation reduces turnaround time.

- Minimized errors: AI-based inspection processes eliminate human error.

- Flexibility: Adapt to different data formats and specific requirements.

- Scalability: Easily adapt to growing data volumes.

Marcus

Dr.-Ing. Marcus Prümmer

Am Weichselgarten 7

91058 Erlangen

Germany

+49 (0)9131 - 691 385

+49 (0)9131 - 691 386

pruemmer(at)chimaera.de